By Jeremy Kichler

Colquitt County CEC

The combination of humidity and moisture this spring has been a great challenge to many hay producers across the state.. The single most important “producer-controlled” factor influencing hay quality is the stage of maturity at harvest. However, unfavorable weather conditions in the Southeast can make it difficult to harvest forages at the proper stage, and can lead to forages becoming overly mature. One way to combat this problem is to use a conditioning-mower, which will greatly aid crop drying for hay producers in this region. Conditioners are designed to crack, strip, or split stems, thus reducing the drying time of the crop. Over the years, studies have shown that the drying rate of a hay crop is 15-25% faster when a conditioner is used. The difference in drying rate is most pronounced in the first 12 hours after cutting, which is very helpful in reducing respiration losses.

County Agents often get questions about selecting mower conditioners. Producers often debate between a flail or roller crimper conditioner. Let’s discuss some points to consider in the selection process.

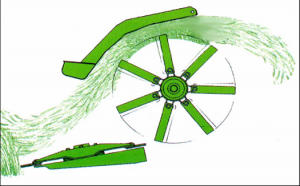

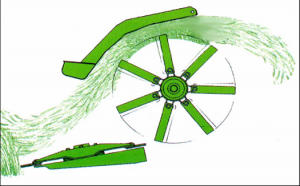

The flail or impeller conditioner is suited more for fined stemmed forages.  The impeller conditioner is composed of v-shaped flails that whip around a rotating drum. The flails are designed to strip the waxy coating off the plant in order to decrease drying time in the field. Impeller conditioners are usually very aggressive and should be avoided when harvesting legume forages.

The impeller conditioner is composed of v-shaped flails that whip around a rotating drum. The flails are designed to strip the waxy coating off the plant in order to decrease drying time in the field. Impeller conditioners are usually very aggressive and should be avoided when harvesting legume forages.

The impeller conditioner is composed of v-shaped flails that whip around a rotating drum. The flails are designed to strip the waxy coating off the plant in order to decrease drying time in the field. Impeller conditioners are usually very aggressive and should be avoided when harvesting legume forages.

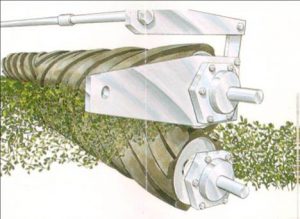

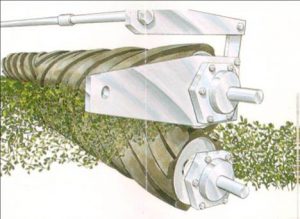

The impeller conditioner is composed of v-shaped flails that whip around a rotating drum. The flails are designed to strip the waxy coating off the plant in order to decrease drying time in the field. Impeller conditioners are usually very aggressive and should be avoided when harvesting legume forages.A roller crimper conditioner consists of intermeshing rubber rolls that crush the stems and leaves of the forage crop. Crimping and crushing newly cut hay often times results in forages that dry faster and more evenly. These types of conditioners are more suited for larger stemmed forages such as alfalfa, pearl millet, and sorghum x sudangrass. The larger stemmed forages often require more time to dry down compared to finer stemmed forages such as bermudagrass. The shorter  drying time will prove to be advantageous if the weather forecast predicts rain. The roller crimper conditioner will generally save a day or more of drying compared to the flail mowers when harvesting the larger stemmed forages mentioned above. Alfalfa producers should also consider roller conditioners because of their association with lower leaf loss.

drying time will prove to be advantageous if the weather forecast predicts rain. The roller crimper conditioner will generally save a day or more of drying compared to the flail mowers when harvesting the larger stemmed forages mentioned above. Alfalfa producers should also consider roller conditioners because of their association with lower leaf loss.

drying time will prove to be advantageous if the weather forecast predicts rain. The roller crimper conditioner will generally save a day or more of drying compared to the flail mowers when harvesting the larger stemmed forages mentioned above. Alfalfa producers should also consider roller conditioners because of their association with lower leaf loss.

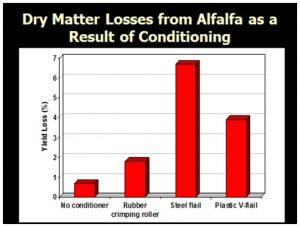

drying time will prove to be advantageous if the weather forecast predicts rain. The roller crimper conditioner will generally save a day or more of drying compared to the flail mowers when harvesting the larger stemmed forages mentioned above. Alfalfa producers should also consider roller conditioners because of their association with lower leaf loss.The figure below shows the dry matter losses from alfalfa as a result of type of conditioner used. Alfalfa losses increased when a plastic or steel flail machine was used compared to a roller or no conditioner.

If you have questions or comments about mower conditioners please contact your local county Extension office.